Did you like the article? Share it!

What is Hot foil in the printing industry?

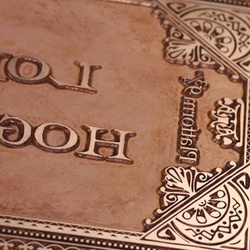

You are probably in contact everyday with hot foil without even without knowing it. You can find it on labels, packaging, even on objects.Do you remember that sparkling goldish detail on that wine label, the wine you drank last night? That is the hotfoil we're talking about.

Let's know more about the story of this printing technique.

Hot foil printingadds value and a personal touch to the simplest of items and delivers a unique finishing touch. The use of it is most of the time linked to luxury items.

A big mistake when foil is mentioned is that people think just about gold foil.

Some of the very first manuscripts ever produced used real gold leaf to decorate intricate calligraphy. This is the reason why we always think about gold when we tak about hot foil. The process of applying raw gold leaf to paper was related to the craft of gilding, in which wafer-thin layers of gold were brushed onto items like bullae (amulets), picture frames, statues, and furniture.

After printing presses became more widely used in Europe in the 18th and 19th centuries, books became the focus of metallic foiling. The most beautiful and expensive books were bound in leather cases which were often embellished with gold leaf.

How does it work the hot foil printing process?

Nowadays, the foiling process doesn’t use real gold leaf. Metallic foils are now made of aluminium or tin, and are combined with a color layer to produce the desired effect.

Hot foil printing a specialized printing process that involves the use of heat, pressure and metal foils to create some shiny details in a wide range of colors and textures.

This process is also called hot stamping or hot foil stamping since the process is largely dependent on the heat for transferring the images from the hot stamp on a chosen surface.

But how can you transfer the foil with a specific design on the choosen susbstrate?

Of course you need a die, a carved metallic plate which is fundamental the stamping process. During hot foiling, heat and pressure are applied to the foil, which is pressed against the substrate supported by this plate.

Let's se how the hot foil stamping plate is made.

A foiling die is prepared for each design depending on the pattern and colour/ types of foil that needs to be used.

There are three different metals that are used to make foiling dies, depending on the cost and application.

1. Magnesium Dies

They are usually made from magnesium, which is a cheap and soft metal that can be easily manipulated into different patterns. They are light in weight, take less time to etch, and heat up very quickly. However, they do not last very long and get damaged after a few thousand runs on the foiling machine.

2. Copper Dies

Copper dies are more expensive than magnesium dies. They take longer to etch and are heavier in weight.

They are more durable than magnesium dies and can produce high-quality designs that last for a longer period of time.

3. Brass Dies

These are the most expensive, and undoubtedly, the sturdiest of all three metals. They are tough and last for many runs. They are usually prepared through CNC systems, which basically use different sized drill bits to etch the designs on the die. This type of die can be used for contemporary hot foil and embossing finishing.

I punzoni per lamina a caldo vengono preparati utilizzando un processo chiamato attacco acido. Ogni punzone può essere riutilizzato più volte e conservato quando non in uso.

Vediamo ora che è fatta una invece una lamina.

The dies are prepared using a process called acid etching. Each die can be reused multiple times and stored when not in use.

Let's see now the hot foil is made.

How a foil is made and how many foils can I choose from?

Foil Stamping involves the use of a specialised multi-layered foil. Typically, the different types of layers in the foil are:

- A polyester carrier layer,

- A release layer,

- Lacquer layers,

- Image layers,

- Colored Layer (we'll see the type of foils later on)

- An outer adhesive layer

The adhesive layer is activated by this heat and pressure, and the release layer melts, attaching the hot foil to the substrate in a permanent way.

Now that you know how a foil is made , let's see which kind of foils can be used on your labels.

In order to achieve various kinds of finishes and designs, different types of foils are used.

These are the main ones:

Metallic Foils

These are the most common types of foils used in the foil stamping process. They give a classic metallic finish to the design and are usually available in gold, silver and copper colours, although other colours are also used.

Pigmented Foils

Pigmented foils produce a matte or glossy non-metallic finish on the design.

Pearlescent Foils

Pearlescent foils add a beautiful pearly shine to the design.

Holographic Foils

These foils are used to produce a wide variety of patterns and special effects on the substrate.

Holographic foils are usually used to prevent counterfeiting.

Scratch Foils

These foils are designed to be easily scratched off by means of a coin or fingernail. It is not permanent as the other foils and can be scratched off easily. This is why they are perfect as a temporary cover for highly sensitive information.

As you can there's plenty of choices. You just have to choose which one is perfect for your design Get started creating your own luxurious label with our instant online estimator, by selecting the Hot foil option in the Finishings tab, otherwise if you need answers or you want to learn more about a particular topic, write us with this form, and a member of the Oppaca Staff will respond as soon as possible.

Next